FLAT GRINDING

FLAT GRINDING

In surface grinding, the grit sizes 24 - 36 - 46 - 54 - 60 - 80 are usually used. With wheels, cup wheels, rings or segments, it always depends on the optimizing of the grinding performance.

We manufacture corresponding grinding wheels for the following surface grinding machines:

Blohm - Elbschliff - ABA - Glauchau - Z&B - Geibel und Hotz - Jung - Waldrich and many other manufacturers

CYLINDRICAL GRINDING and PROFILE GRINDING

CYLINDRICAL GRINDING and PROFILE GRINDING

For cylindrical grinding operations, finer grits, grit 46 - 54 - 60 - 80 - 100, can be used, since there is tangential contact (workpiece / grinding wheel) and thus a lower grinding pressure is generated.

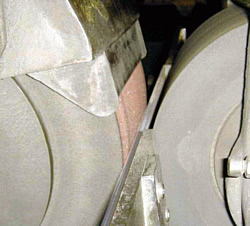

CENTERLESS GRINDING

For centerless grinding, grinding wheels with larger widths are used. Up to a wheel width of 500mm, we can manufacture in one piece, then in multi pieces.

For this grinding operation there are 3 types of grinding:

- Throughfeed grinding (cylindrical grinding)

- Plunge grinding (form grinding)

- Stop grinding (cylindrical grinding)

For centerless cylindrical grinding, the grinding wheel and regulating wheel must be perfectly matched to each other to achieve the best possible result.

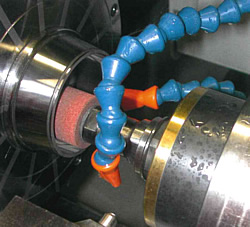

INTERNAL GRINDING

We manufacture internal grinding wheels from ø5 mm to ø150 mm depending on your requirements.

For internal grinding it should be noted that the diameter of the grinding wheel is only about one third of the diameter of the workpiece bore. This provides maximum grinding performance, while reducing the heat load in the grinding zone.

Ø grinding wheel < 1/3 Øworkpiece bore

For roughing and fine grinding for materials from 58-65 HRc, we recommend using electroplated, ceramic or resin bonded CBN grit. For materials above 65 HRc we recommend the use of appropriate diamond tools.