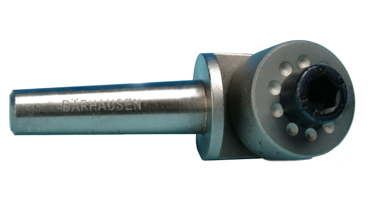

SINGLE POINT DIAMOND DRESSER

Dressors with single diamonds are used for

Dressors with single diamonds are used for

Dressing and profiling of grinding wheels in vitrified bond.

Quality 363 - with 3 ground points

Quality 453 - with 3 natural tips

Bärhausen always produces with centered set diamonds in a sintered head. We supply all shank shapes.

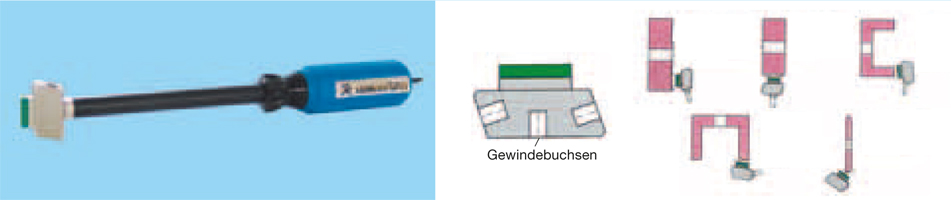

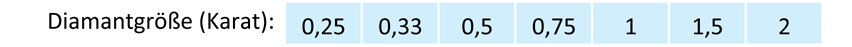

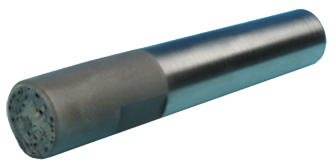

MULTI-POINT DRESSER

BD Series: Dresser with sintered diamond head

BD Series: Dresser with sintered diamond head

used for grinding wheel diameter:

BD 110 250 x 20 to 300 x 40 mm

BD 120 400 x 32 to 500 x 40 mm

BD 130 600 x 80 to 750 x 63 mm

BD 140 900 x 63 to 1250 x 80 mm

Position of the diamond head:

01 = straight

02 = 15° angle

Application for grinding wheel grain:

Application for grinding wheel grain:

A = grit 16 – 36

C = grit 46 – 60

E = grit 80 – 180

F = 220 grit and finer

Bond:

B1 = very hard, for SIC grinding wheels

B6 = Standard, for EK+NK wheels

Infeed per dressing pass:

fine grinding = approx. 0.01 mm

rough grinding = approx. 0.02 mm

Order example:

BD 110 – 01 – E – B6, shank 10 x 40 mm

DRESSING WHEEL - R1800

Main field of application: cylindrical grinding machines with wheel diameter 400 - 800 mm and a wheel width up to 120 mm

R Series: On the dressing wheel there are (diagonally arranged over a width of 10 mm) 20 rows of 4/5 needle diamonds each. On the two planar sides of the dressing wheel, 10 ball cups are milled into each side to lock it in place, into which a pin on the shaft holder can engage.

R Series: On the dressing wheel there are (diagonally arranged over a width of 10 mm) 20 rows of 4/5 needle diamonds each. On the two planar sides of the dressing wheel, 10 ball cups are milled into each side to lock it in place, into which a pin on the shaft holder can engage.

The fixing is done with an Socket head screw. If there is a row of needle diamonds (4/5 pieces), loosen the screw and turn the dressing wheel until the pin engages in the next calotte and tighten the screw again. Now the tool is at its maximum performance again.

Set of Diamond:

3 carat = 4 needle diamonds per row

5 carat = 5 needle diamonds per row

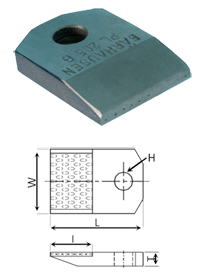

DRESSING FLIESEN IN CVD, PKD, MKD AND NEEDLE DIAMONDS

PL Series:

This dresser is mainly suitable for cylindrical dressing of the diameter of grinding wheels and for cylindrical profiles.

application:

This dresser must be used upright and off-axis of the grinding wheel.

infeed:

0,02 – 0,04 mm

PROFILING DIAMONDS TYPE DIAFORM

Precise cutting geometry

Hochpräzise High-precision rounded radius

Diamond size (carat): 0,33 / 0,5 / 0,75

DIAMOND HAND DRESSER - TYPE 123

for dressing vitrified grinding wheels

DIAMOND ROTARY DRESSING TOOLS

Diamond form rolls & diamond profile rolls are rotary dressing tools for dressing conventional vitrified grinding wheels and vitrified bonded CBN wheels.

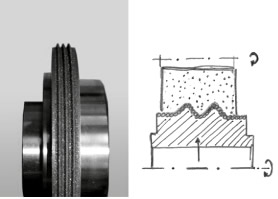

Diamond profile roll

Diamond profile roll

This profile roller aligns the entire profile to the grinding wheel in the infeed process. These profile rollers are used primarily in the work areas of series production, since the low dressing time and long service life result in high and efficient series production.

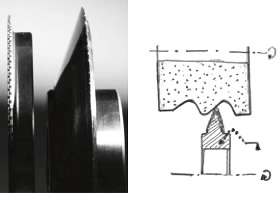

Diamond form roll

Diamond form roll

The form roll uses a CNC control to dress the grinding wheel with any profile. They can be used in all areas of grinding technology - from small series to medium series production. With this procedure, changes in the grinding wheel shape can also be implemented quickly. All types of shaping rollers are available.

DRESSING MACHINE BA-100 AND BAS-500

Dressing machine BA-100

Dressing machine BA-100

This machine is designed for dressing metal, ceramic and resin bonded Diamond and CBN grinding wheels. The pneumatic drive and the automatic centrifugal brake ensure economical working. The BA-100 is used for dressing on cylindrical, surface and tool grinding machines.

Dressing machine BAS-500

Dressing machine BAS-500

This machine is designed for dressing metal, ceramic and resin bonded diamond and CBN grinding wheels as well as conventional grinding wheels. The electric drive and the optional control offer all possibilities of rotary dressing.

VITRIFIED DRESSING WHEELS

Maße: Ø 100 x 25 x 20 mm D/B=Diamant /CBN

Maße: Ø 100 x 25 x 20 mm D/B=Diamant /CBN

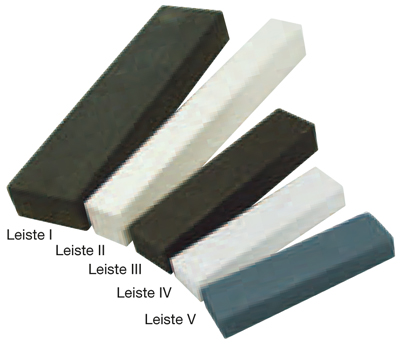

DRESSING STICKS

Leiste I 200 x 50 x 25 mm – 1C 120 L6 B

Leiste I 200 x 50 x 25 mm – 1C 120 L6 B

Leiste II 200 x 25 x 25 mm – 22A 320 H8 V16C

Leiste III 125 x 20 x 30 mm – 90C 320 H8 V16L

Leiste IV 100 x 15 x 25 mm – 22A 320 H8 V16L

Leiste V 100 x 15 x 25 mm – 90C 320 H8 V16L